Your How to make tongue and groove images are ready in this website. How to make tongue and groove are a topic that is being searched for and liked by netizens today. You can Get the How to make tongue and groove files here. Get all royalty-free images.

If you’re looking for how to make tongue and groove pictures information connected with to the how to make tongue and groove keyword, you have come to the ideal site. Our website always gives you suggestions for downloading the maximum quality video and image content, please kindly surf and find more informative video content and images that fit your interests.

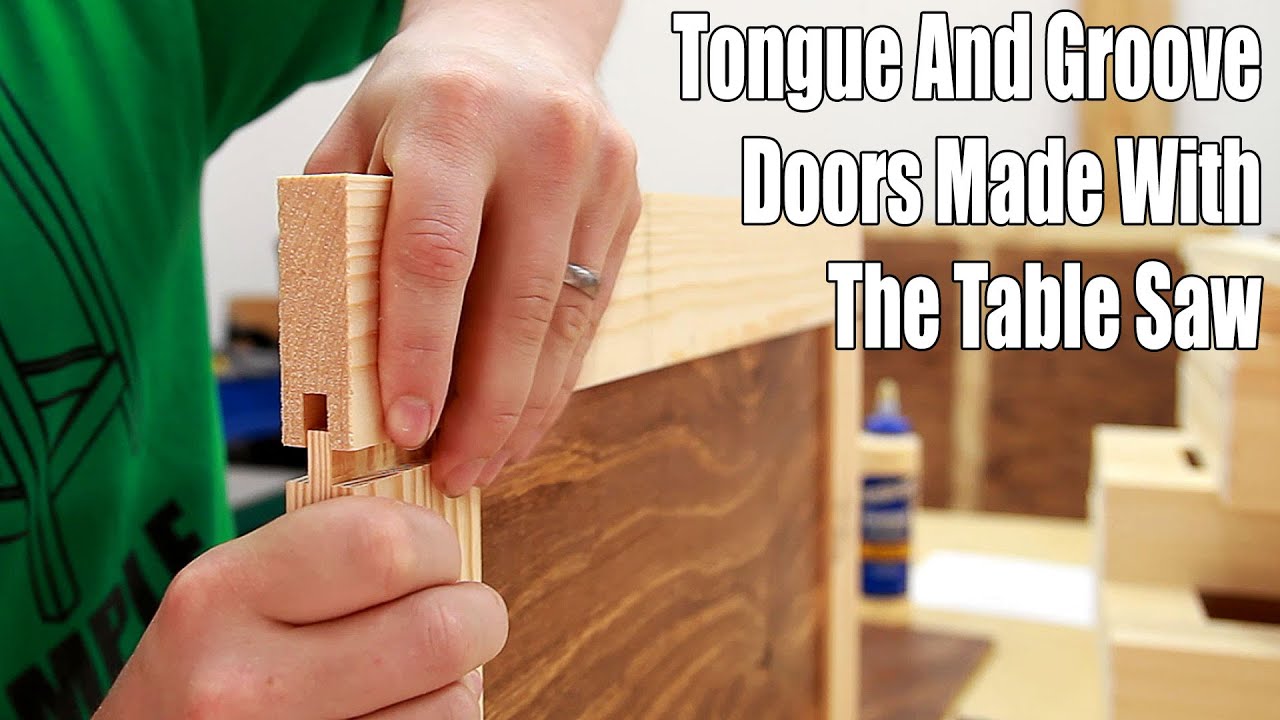

How To Make Tongue And Groove. When the tongue nearly fits the slot use the grooved workpiece to dial in the final bit height. How to Make Tongue and Groove Joints Step1. However we recommend using glue even if you dont need it for strength. I show the processes to turn a fallen tree into valuable tongue and groove flooring.

How To Make A Tongue And Groove Joint Tongue And Groove Tounge And Groove Woodworking Joints From ro.pinterest.com

How To Make A Tongue And Groove Joint Tongue And Groove Tounge And Groove Woodworking Joints From ro.pinterest.com

3 Ways to Create your Hardwood Floor Panels with Tongue and Groove Joint using 1 Saw Blade 2 Router Bits or 3 Shaper Cutters. This step is not entirely necessary if you have some experience using a router but if not you need to mark the giving and receiving ends on your boards. Set up cut in router table. This is one of the most common looks with tongue and groove styles. The first step is to make the groove and the. How deep should a tongue and groove joint be.

Having square wood is the key to this joint.

A standard blade is adequate for thin stock however. You can use a clamp to wring the joint tightly. First is to prevent problems during assembly. They also add a. How deep should a tongue and groove joint be. However we recommend using glue even if you dont need it for strength.

Source: pinterest.com

Source: pinterest.com

Set blade height Remember that the height of the blade determines the size of the tongue and depth of the groove. They also add a. But with the right bits the joints can be made just as easily on a router table. Then repeat raising the bit about 18-in. The reason for this is two-fold.

Source: pinterest.com

Source: pinterest.com

The log is white oakMy wide belt sander newer version. Making Tongue and Groove Flooring. Tongue and groove boards are a wooden planking system that joins and adjacent board by interlocking the ridges and grooves built into the sides of the pieces. This step is not entirely necessary if you have some experience using a router but if not you need to mark the giving and receiving ends on your boards. Tongue-and-groove joints are commonly made on a table saw.

Source: pinterest.com

Source: pinterest.com

The log is white oakMy wide belt sander newer version. Every woodworker should be familiar with cutting them on the table saw. They also add a. Set blade height Remember that the height of the blade determines the size of the tongue and depth of the groove. If you want tongue and groove joints that fit together snugly they should be as tight as possible.

Source: pinterest.com

Source: pinterest.com

Because of that this is one of the. Raise the bit until it just intersects the bottom wall of. I show the processes to turn a fallen tree into valuable tongue and groove flooring. The log is white oakMy wide belt sander newer version. Click to see full answer.

Source: pinterest.com

Source: pinterest.com

If you want tongue and groove joints that fit together snugly they should be as tight as possible. You can use a clamp to wring the joint tightly. How tight should the tongue and groove be. With each round of passes to remove more waste. They also add a.

Source: pinterest.com

Source: pinterest.com

Click to see full answer. This joint is really only used for timber boards so the first thing you must do is measure and cut up some timber boards to your required length. Same bit can be used to cut both pieces of joint. With each round of passes to remove more waste. The groove should ALWAYS be slightly deeper than the tongue is long by as much as 116 for 3-inch wide boards.

Source: pinterest.com

Source: pinterest.com

How to Make Tongue and Groove on a Table Saw Easily Making Tongue and Groove on a Table Saw. Set blade height Remember that the height of the blade determines the size of the tongue and depth of the groove. 3 Ways to Create your Hardwood Floor Panels with Tongue and Groove Joint using 1 Saw Blade 2 Router Bits or 3 Shaper Cutters. Tongue and groove plural tongue and grooves or tongues and grooves A joint in flooring or panelling made by fitting a ridge tongue along the edge of one board into a corresponding slot groove on another. Put boards together for tongue and groove joint.

Source: pinterest.com

Source: pinterest.com

The long thin strips make the room look elongated and more spacious. How deep should a tongue and groove joint be. Making Tongue and Groove Flooring - YouTube. Make sure that the router is unplugged when you are changing the router bit. Having square wood is the key to this joint.

Source: ro.pinterest.com

Source: ro.pinterest.com

Raise the bit until it just intersects the bottom wall of. Tips for Accuracy While Making Tongue and Groove on Table Saw. I show the processes to turn a fallen tree into valuable tongue and groove flooring. Set blade height Remember that the height of the blade determines the size of the tongue and depth of the groove. Tongue and groove boards are a wooden planking system that joins and adjacent board by interlocking the ridges and grooves built into the sides of the pieces.

Source: pinterest.com

Source: pinterest.com

When the tongue nearly fits the slot use the grooved workpiece to dial in the final bit height. The reason for this is two-fold. How to Make Tongue and Groove Joints Step1. I show the processes to turn a fallen tree into valuable tongue and groove flooring. The long thin strips make the room look elongated and more spacious.

Source: pinterest.com

Source: pinterest.com

The first step is to make the groove and the. Now adjust the tongue cutter and line up with the tongue. A standard blade is adequate for thin stock however. You have to do this in two steps. Solid boards with tongues on the right sides of the boards and grooves on the left sides.

Source: pinterest.com

Source: pinterest.com

3 Ways to Create your Hardwood Floor Panels with Tongue and Groove Joint using 1 Saw Blade 2 Router Bits or 3 Shaper Cutters. This step is not entirely necessary if you have some experience using a router but if not you need to mark the giving and receiving ends on your boards. Raise the bit until it just intersects the bottom wall of. You have to do this in two steps. Tongue and groove installed surfaces also tend to be more level than other methods of installation.

Source: pl.pinterest.com

Source: pl.pinterest.com

The long thin strips make the room look elongated and more spacious. Here are some fun ideas on how to use tongue and groove paneling in your home. Making Tongue and Groove Flooring. Put boards together for tongue and groove joint. How to Make Tongue and Groove V-Groove Boards Rockler Skill Builders - YouTube.

Source: pinterest.com

Source: pinterest.com

Make sure that the router is unplugged when you are changing the router bit. 3 Ways to Create your Hardwood Floor Panels with Tongue and Groove Joint using 1 Saw Blade 2 Router Bits or 3 Shaper Cutters. However we recommend using glue even if you dont need it for strength. The tongue-and-groove is one of the most basic and useful joints. I show the processes to turn a fallen tree into valuable tongue and groove flooring.

Source: pinterest.com

Source: pinterest.com

Make sure that the router is unplugged when you are changing the router bit. The long thin strips make the room look elongated and more spacious. However we recommend using glue even if you dont need it for strength. Click to see full answer. How to Make a Tongue and Groove Joint with Hand Tools - YouTube.

Source: pinterest.com

Source: pinterest.com

Use bit for cutting tongue. When cutting joints make sure the router table is clear of sawdust. Set blade height Remember that the height of the blade determines the size of the tongue and depth of the groove. Same bit can be used to cut both pieces of joint. Here are some fun ideas on how to use tongue and groove paneling in your home.

Source: pinterest.com

Source: pinterest.com

Tongue-and-groove joints are commonly made on a table saw. Put boards together for tongue and groove joint. Now adjust the tongue cutter and line up with the tongue. Use bit for cutting tongue. Making Tongue and Groove Flooring.

Source: br.pinterest.com

Source: br.pinterest.com

Every woodworker should be familiar with cutting them on the table saw. Then repeat raising the bit about 18-in. You can buy tongue and groove panels from a hardware store or make them yourself if youre handy with tools. This is one of the most common looks with tongue and groove styles. Use bit for cutting tongue.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to make tongue and groove by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.