Your How to make carbon fiber images are ready in this website. How to make carbon fiber are a topic that is being searched for and liked by netizens now. You can Download the How to make carbon fiber files here. Find and Download all free vectors.

If you’re searching for how to make carbon fiber pictures information linked to the how to make carbon fiber interest, you have visit the right blog. Our site frequently gives you hints for seeking the highest quality video and image content, please kindly surf and find more informative video content and graphics that match your interests.

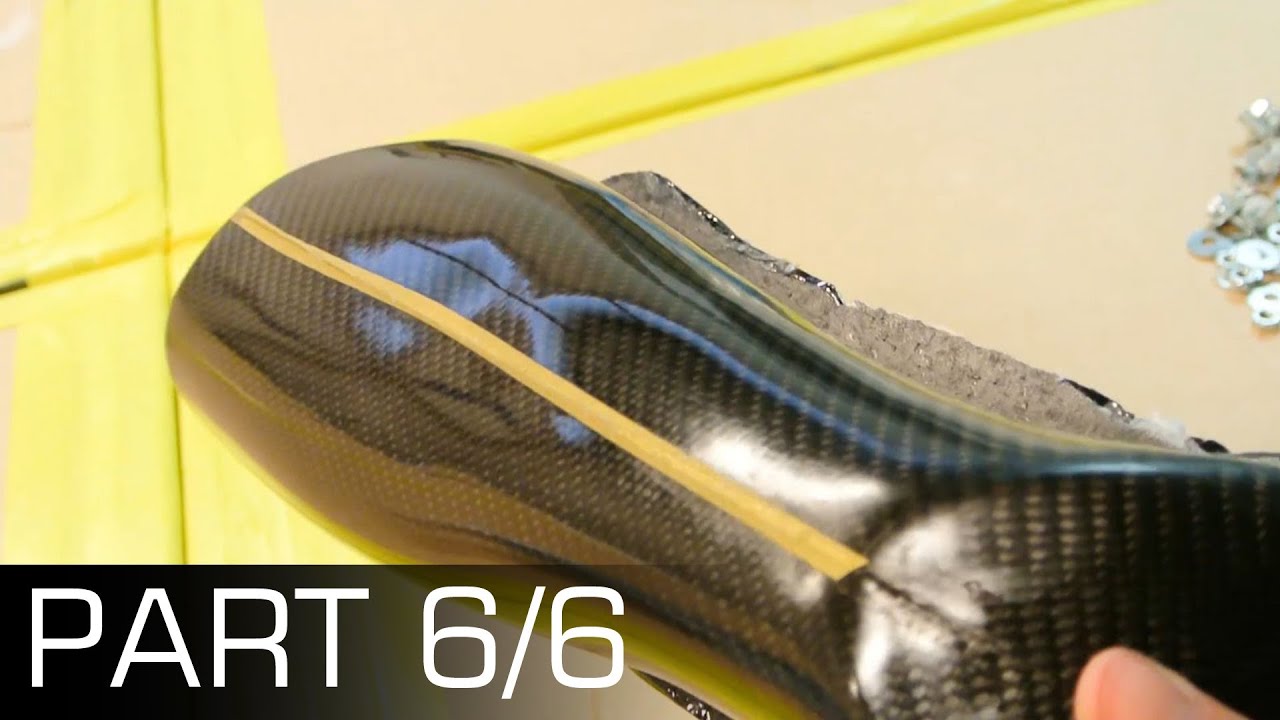

How To Make Carbon Fiber. This method requires the most skills to create high-quality parts but it is also the least expensive workflow with the lowest requirements to get started with making DIY carbon fiber parts. The first high-performance carbon fiber. In simplest terms carbon fiber is produced by pyrolysis of an organic precursor fiber in an inert atmosphere at temperatures above 982C1800F. Carbon fiber prepreg is laid into the mold placed in a vacuum bag and cured in an autoclave at the required temperature and pressure settings.

Get Amazing Motorcycle Gear Service At Revzilla Make Your Own Carbon Fiber Motorcycle Parts Carbon Fiber Moldings Look Great On A B Carbon Fiber Carbon Fiber From nl.pinterest.com

Get Amazing Motorcycle Gear Service At Revzilla Make Your Own Carbon Fiber Motorcycle Parts Carbon Fiber Moldings Look Great On A B Carbon Fiber Carbon Fiber From nl.pinterest.com

Creating a Good Surface. This method requires the most skills to create high-quality parts but it is also the least expensive workflow with the lowest requirements to get started with making DIY carbon fiber parts. If you are new to carbon fiber parts manufacturing and not equipped yet we would. Videos you watch may be added to the TVs watch history and influence TV. Carbon fiber kits Heute bestellen versandkostenfrei. Detailed tutorial covering some basic theory and practical advice on how to make a carbon fibrefiber sheet using different manufacturing processes of hand.

How To Make Your Own Carbon Fiber Fibre Parts.

Method 2 Method 2 of 4. Creating a Good Surface. After cutting the shape clean your object and apply the vinyl to itThen cut off excess vinyl using your object as a template. Without oxygen the fiber cannot burn. Ad Top-Preise für Carbon Fiber Kits im Vergleich. Before you can start making something from.

Source: pinterest.com

Source: pinterest.com

Method 2 Method 2 of 4. The Subaru Impreza has a gap at the top of. Ad Get A Very Special Offer On Simply Carbon Fiber Right Now - Limited Time Offer. Carbon fiber manufacture however is a complex undertaking. How to Make Carbon Fiber Method 1 Method 1 of 4.

Source: it.pinterest.com

Source: it.pinterest.com

Creating a Good Surface. For a complete materials list including l. This method requires the most skills to create high-quality parts but it is also the least expensive workflow with the lowest requirements to get started with making DIY carbon fiber parts. Method 2 Method 2 of 4. Ad Top-Preise für Carbon Fiber Kits im Vergleich.

Source: in.pinterest.com

Source: in.pinterest.com

The three different manufacturing methods well be looking at to make our sheets are a simple hand lay-up process using dry carbon fibre fabric hand laminated using epoxy resin resin infusion where well be using a vacuum process to infuse epoxy resin through dry carbon reinforcement and finally oven cured prepreg where well use uncured prepreg. How to make DIY carbon fiber parts at home with wet lay - YouTube. Ad Top-Preise für Carbon Fiber Kits im Vergleich. Find an appropriate mold. Place it on the Carbon Fiber and cut around your item being sure to leave a little bit of vinyl on the edges so it can be trimmed exactly.

Source: pinterest.com

Source: pinterest.com

The Original Creators of the Full Carbon Fiber Glasses Sunglasses AirPods Cases More. I walk you through the entire process of making a carbon fiber replica of a part including how to make the mold. The Original Creators of the Full Carbon Fiber Glasses Sunglasses AirPods Cases More. Step 1 3D Print the pattern Step 2 Post-process the pattern Step 3 Create mold from pattern Step 4 Use mold to. Find an appropriate mold.

Source: pinterest.com

Source: pinterest.com

In wet lay-up the fiber is cut and laid into the mold then resin is applied via a brush roller or spray gun. The Subaru Impreza has a gap at the top of. Videos you watch may be added to the TVs watch history and influence TV. Ad Get A Very Special Offer On Simply Carbon Fiber Right Now - Limited Time Offer. How to make DIY carbon fiber parts at home with wet lay - YouTube.

Source: pinterest.com

Source: pinterest.com

The precursor is drawn into long strands heated to a very high temperature without allowing them to come in contact with oxygen. The process of making carbon fiber is quite unique as it is part mechanical and part chemical. Videos you watch may be added to the TVs watch history and influence TV. The first high-performance carbon fiber. How To Make Your Own Carbon Fiber Fibre Parts.

Source: pinterest.com

Source: pinterest.com

In simplest terms carbon fiber is produced by pyrolysis of an organic precursor fiber in an inert atmosphere at temperatures above 982C1800F. The process of making carbon fiber is quite unique as it is part mechanical and part chemical. In simplest terms carbon fiber is produced by pyrolysis of an organic precursor fiber in an inert atmosphere at temperatures above 982C1800F. Precursor To produce carbon fiber an organic polymer precursor is needed. In wet lay-up the fiber is cut and laid into the mold then resin is applied via a brush roller or spray gun.

Source: pinterest.com

Source: pinterest.com

Before you can start making something from. After cutting the shape clean your object and apply the vinyl to itThen cut off excess vinyl using your object as a template. Method 2 Method 2 of 4. In simplest terms carbon fiber is produced by pyrolysis of an organic precursor fiber in an inert atmosphere at temperatures above 982C1800F. Ad Get A Very Special Offer On Simply Carbon Fiber Right Now - Limited Time Offer.

Source: pinterest.com

Source: pinterest.com

Carbon fiber manufacture however is a complex undertaking. The process of making carbon fiber is quite unique as it is part mechanical and part chemical. After cutting the shape clean your object and apply the vinyl to itThen cut off excess vinyl using your object as a template. Find an appropriate mold. Videos you watch may be added to the TVs watch history and influence TV.

Source: pinterest.com

Source: pinterest.com

Videos you watch may be added to the TVs watch history and influence TV. Detailed tutorial covering some basic theory and practical advice on how to make a carbon fibrefiber sheet using different manufacturing processes of hand. Ad Top-Preise für Carbon Fiber Kits im Vergleich. Our first successful Carbon Fibre part. This method requires the most skills to create high-quality parts but it is also the least expensive workflow with the lowest requirements to get started with making DIY carbon fiber parts.

Source: pinterest.com

Source: pinterest.com

Precursor To produce carbon fiber an organic polymer precursor is needed. Ad Get A Very Special Offer On Simply Carbon Fiber Right Now - Limited Time Offer. The Subaru Impreza has a gap at the top of. Carbon fiber prepreg is laid into the mold placed in a vacuum bag and cured in an autoclave at the required temperature and pressure settings. This method requires the most skills to create high-quality parts but it is also the least expensive workflow with the lowest requirements to get started with making DIY carbon fiber parts.

Source: pinterest.com

Source: pinterest.com

The precursor is drawn into long strands heated to a very high temperature without allowing them to come in contact with oxygen. Ad Get A Very Special Offer On Simply Carbon Fiber Right Now - Limited Time Offer. If playback doesnt begin shortly try restarting your device. Carbon fiber manufacture however is a complex undertaking. Before you can start making something from.

Source: pinterest.com

Source: pinterest.com

This raw material is processed with heat and chemical agents to convert it to carbon fiber. For a complete materials list including l. Find an appropriate mold. Precursor To produce carbon fiber an organic polymer precursor is needed. If you are new to carbon fiber parts manufacturing and not equipped yet we would.

Source: pinterest.com

Source: pinterest.com

Our first successful Carbon Fibre part. The Original Creators of the Full Carbon Fiber Glasses Sunglasses AirPods Cases More. Before you can start making something from. The Subaru Impreza has a gap at the top of. How To Make Your Own Carbon Fiber Fibre Parts.

Source: pinterest.com

Source: pinterest.com

The three different manufacturing methods well be looking at to make our sheets are a simple hand lay-up process using dry carbon fibre fabric hand laminated using epoxy resin resin infusion where well be using a vacuum process to infuse epoxy resin through dry carbon reinforcement and finally oven cured prepreg where well use uncured prepreg. How to Make Carbon Fiber Method 1 Method 1 of 4. Detailed tutorial covering some basic theory and practical advice on how to make a carbon fibrefiber sheet using different manufacturing processes of hand. The Subaru Impreza has a gap at the top of. If you are new to carbon fiber parts manufacturing and not equipped yet we would.

Source: pinterest.com

Source: pinterest.com

Method 2 Method 2 of 4. This raw material is processed with heat and chemical agents to convert it to carbon fiber. The first high-performance carbon fiber. In wet lay-up the fiber is cut and laid into the mold then resin is applied via a brush roller or spray gun. Videos you watch may be added to the TVs watch history and influence TV.

Source: pinterest.com

Source: pinterest.com

Detailed tutorial covering some basic theory and practical advice on how to make a carbon fibrefiber sheet using different manufacturing processes of hand. The process of making carbon fiber is quite unique as it is part mechanical and part chemical. Ad Get A Very Special Offer On Simply Carbon Fiber Right Now - Limited Time Offer. I walk you through the entire process of making a carbon fiber replica of a part including how to make the mold. How to make DIY carbon fiber parts at home with wet lay - YouTube.

Source: pinterest.com

Source: pinterest.com

The process of making carbon fiber is quite unique as it is part mechanical and part chemical. Method 2 Method 2 of 4. The three different manufacturing methods well be looking at to make our sheets are a simple hand lay-up process using dry carbon fibre fabric hand laminated using epoxy resin resin infusion where well be using a vacuum process to infuse epoxy resin through dry carbon reinforcement and finally oven cured prepreg where well use uncured prepreg. Without oxygen the fiber cannot burn. How to Make Carbon Fiber Method 1 Method 1 of 4.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title how to make carbon fiber by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.