Your How to make a wire stripper images are ready in this website. How to make a wire stripper are a topic that is being searched for and liked by netizens now. You can Get the How to make a wire stripper files here. Find and Download all free photos.

If you’re looking for how to make a wire stripper pictures information linked to the how to make a wire stripper interest, you have visit the ideal site. Our site always provides you with hints for viewing the highest quality video and image content, please kindly search and locate more informative video articles and graphics that fit your interests.

How To Make A Wire Stripper. Give appropriate spacing of about an inch to an inch-and-a-half from the tip. However if youre using an automatic wire stripper then you can skip this step altogether. Adjust the blades to compensate when you need more or less wire than this. Once youve determined the correct gauge place the wire into the jaws of the stripper.

Pin On Metal Working Projects From pinterest.com

Pin On Metal Working Projects From pinterest.com

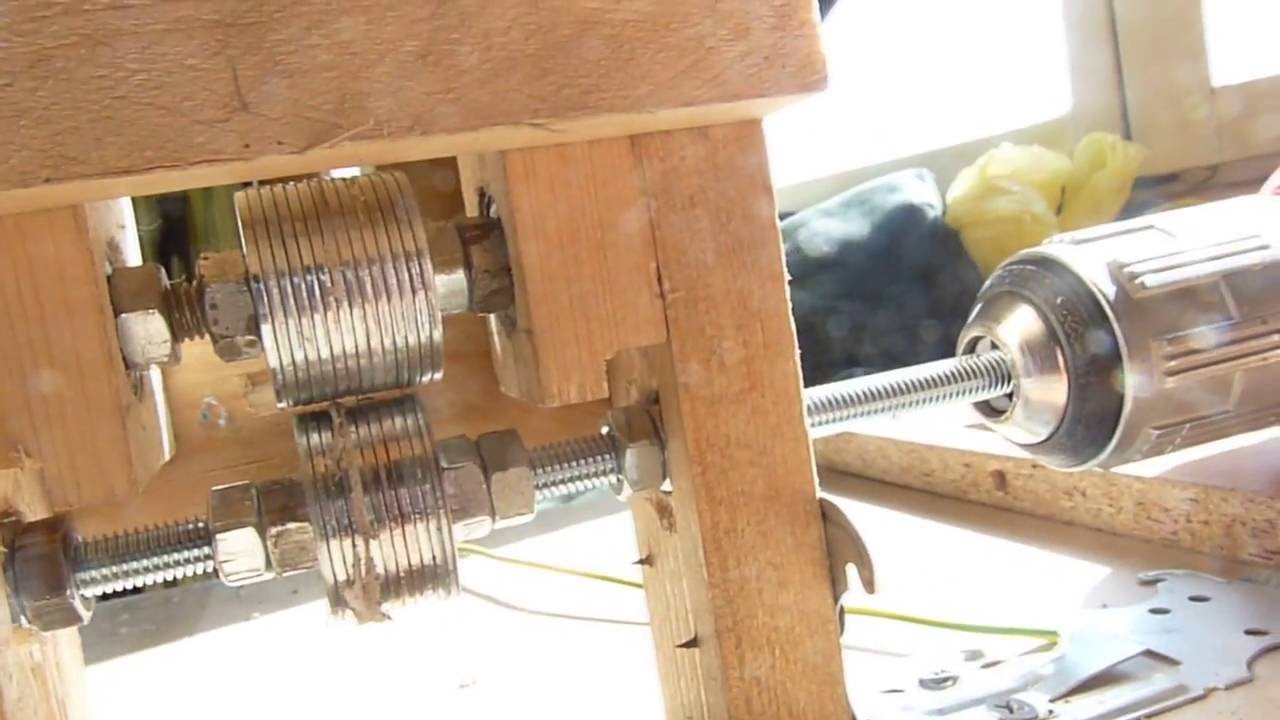

Squeeze the handles just enough to cut into the insulation and spin the tool in a circle so you make a cut all the way around the wire. Ad Kostenloser Versand verfügbar. Using a file clean up the cuts. We have just make one homemade wire striper lets test it. Easy to use. Lay a piece of the wire to be stripped on a flat surface.

From a flat bar 8mm thick cut a piece 75x30mm and refine smooth the edges by a file also do an orientation marck.

Ad EASTONTECH was founded in 2003 with ISO 9001 and CE certification. Measure out the lengths of wire that you need and cut them. Squeeze the handles just enough to cut into the insulation and spin the tool in a circle so you make a cut all the way around the wire. I just used the knife. A wire stripper is a must-have for wiremen used to remove the plastic cover of wire without damaging the inner core. The wire itself produces a gap between these two plates.

Source: pinterest.com

Source: pinterest.com

Because of the working mechanism its easy to make one in your garage. This is typically all youll need to strip to attach the wire to a terminal or tie it to another wire. Then place several thinner plates between the two you just sandwiched the wire with but set these on top of the wire. One of the best ways for stripping scrap copper wire s is to use a Multi-Feed wire stripping machine. How To Make A Wire Stripper DIY A wire stripper is not a complicated tool for the electrician.

Source: pinterest.com

Source: pinterest.com

Set the stripper blades near the end of the wire. Ad EASTONTECH was founded in 2003 with ISO 9001 and CE certification. However if youre using an automatic wire stripper then you can skip this step altogether. In terms of construction wire stripper is mostly made of steel while its coating is covered by rubber for more comfort. When you twist the bolt out of the hole the threads in the hole realign the threads on the cut end of the bolt.

Source: pinterest.com

Source: pinterest.com

We are here to guide you to make your wire stripper without having any problems. All you need is a piece of wood a razor blade a drill and a. More Than 10 Years Of Experience in TheMachineryManufacturing. Then place several thinner plates between the two you just sandwiched the wire with but set these on top of the wire. A compound automatic wire strippers short cutter limits it to fewer notches and a smaller range of wire sizes than most other types of wire strippers.

Source: pinterest.com

Source: pinterest.com

Adjust the blades to compensate when you need more or less wire than this. Set the stripper blades near the end of the wire. Basic Cable Wire Stripper. While keeping the jaws closed. And the raw materials should give a surprise featuring a wooden peg pencil sharpener screwdriver drill bit.

Source: in.pinterest.com

Source: in.pinterest.com

Set the stripper blades near the end of the wire. Move the blades about 12 to 34 inch 13 to 19 mm from the end of the wire. Gently close the wire strippers around the insulation about 1 inch from the end of the wire. Ad Kostenloser Versand verfügbar. When you twist the bolt out of the hole the threads in the hole realign the threads on the cut end of the bolt.

Source: pinterest.com

Source: pinterest.com

From a flat bar 8mm thick cut a piece 75x30mm and refine smooth the edges by a file also do an orientation marck. With some simple utility you can do it. Gently close the wire strippers around the insulation about 1 inch from the end of the wire. Measure out the lengths of wire that you need and cut them. Sandwich the wire with two pieces of the plate material.

Source: pinterest.com

Source: pinterest.com

You can use your utility knife or scissors if the utility knife doesnt make it through. Sandwich the wire with two pieces of the plate material. Just put the wire into the right size feed hole and the machine does the rest. Increase the center holes to ø10mm and then to ø165mm. Several thicknesses of metal or.

Source: pinterest.com

Source: pinterest.com

Then without easing your grip pull the wire strippers sharply down to the end of the wire. Wire Stripper Designed only for wires Offers guides for proper cutting length Combination Wire Stripper. Easy to use. Once done close the wire strippers and let them cut through the wires insulation. Give appropriate spacing of about an inch to an inch-and-a-half from the tip.

Source: pinterest.com

Source: pinterest.com

Also the handles can be either in straight or curved sharp. We have just make one homemade wire striper lets test it. Squeeze the handles just enough to cut into the insulation and spin the tool in a circle so you make a cut all the way around the wire. Share it with us. More Than 10 Years Of Experience in TheMachineryManufacturing.

Source: pinterest.com

Source: pinterest.com

Using a countersink clean up the edges of the holes. Give appropriate spacing of about an inch to an inch-and-a-half from the tip. In terms of construction wire stripper is mostly made of steel while its coating is covered by rubber for more comfort. More Than 10 Years Of Experience in TheMachineryManufacturing. Move the blades about 12 to 34 inch 13 to 19 mm from the end of the wire.

Source: pinterest.com

Source: pinterest.com

The video guidance reveals an amazingly visual method to craft the machine. Then place several thinner plates between the two you just sandwiched the wire with but set these on top of the wire. Increase the center holes to ø10mm and then to ø165mm. Give appropriate spacing of about an inch to an inch-and-a-half from the tip. Ad EASTONTECH was founded in 2003 with ISO 9001 and CE certification.

Source: pinterest.com

Source: pinterest.com

More Than 10 Years Of Experience in TheMachineryManufacturing. Ad EASTONTECH was founded in 2003 with ISO 9001 and CE certification. The video guidance reveals an amazingly visual method to craft the machine. However if youre using an automatic wire stripper then you can skip this step altogether. A wire stripper is a must-have for wiremen used to remove the plastic cover of wire without damaging the inner core.

Source: pinterest.com

Source: pinterest.com

Using a countersink clean up the edges of the holes. If you decide to cut using the knife position your fingerthumb on top of. Then without easing your grip pull the wire strippers sharply down to the end of the wire. More Than 10 Years Of Experience in TheMachineryManufacturing. How To Make A Wire Stripper DIY A wire stripper is not a complicated tool for the electrician.

Source: pinterest.com

Source: pinterest.com

Set the stripper blades near the end of the wire. Then place several thinner plates between the two you just sandwiched the wire with but set these on top of the wire. In terms of construction wire stripper is mostly made of steel while its coating is covered by rubber for more comfort. Check out how to build this simple wire stripper to help make scrapping wire easier quicker. Move the blades about 12 to 34 inch 13 to 19 mm from the end of the wire.

Source: es.pinterest.com

Source: es.pinterest.com

When you twist the bolt out of the hole the threads in the hole realign the threads on the cut end of the bolt. Lay a piece of the wire to be stripped on a flat surface. Then the wire is fixed or connected with another line or the terminal. The insulation should come free without damaging the. However if youre using an automatic wire stripper then you can skip this step altogether.

Source: pinterest.com

Source: pinterest.com

Also the handles can be either in straight or curved sharp. Increase the center holes to ø10mm and then to ø165mm. You dont have to create some bulky time-consuming precisely measured assembly. And the raw materials should give a surprise featuring a wooden peg pencil sharpener screwdriver drill bit. Lay a piece of the wire to be stripped on a flat surface.

Source: pinterest.com

Source: pinterest.com

Then the wire is fixed or connected with another line or the terminal. Several thicknesses of metal or. When you twist the bolt out of the hole the threads in the hole realign the threads on the cut end of the bolt. More Than 10 Years Of Experience in TheMachineryManufacturing. Ad EASTONTECH was founded in 2003 with ISO 9001 and CE certification.

Source: pinterest.com

Source: pinterest.com

And the raw materials should give a surprise featuring a wooden peg pencil sharpener screwdriver drill bit. Ad EASTONTECH was founded in 2003 with ISO 9001 and CE certification. Lay a piece of the wire to be stripped on a flat surface. All wire strippers are inherently limited to those wire sizes the cutting jaw notches will accommodate. Using a file clean up the cuts.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to make a wire stripper by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.