Your How to make a table saw fence images are ready in this website. How to make a table saw fence are a topic that is being searched for and liked by netizens today. You can Get the How to make a table saw fence files here. Download all royalty-free images.

If you’re looking for how to make a table saw fence images information related to the how to make a table saw fence interest, you have come to the right blog. Our site frequently gives you hints for refferencing the highest quality video and image content, please kindly hunt and find more enlightening video content and graphics that match your interests.

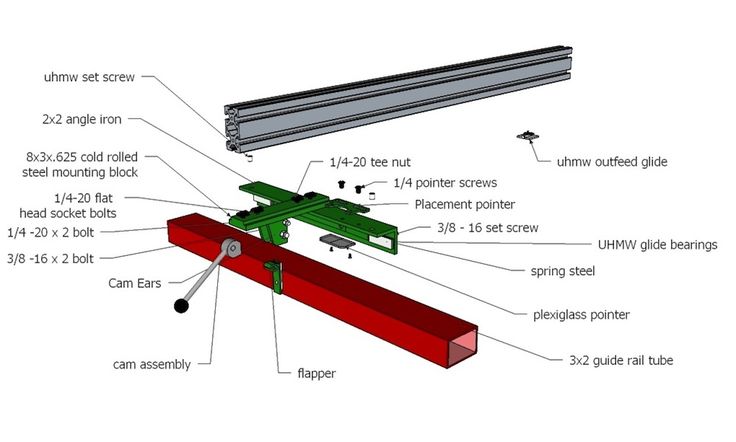

How To Make A Table Saw Fence. Sometimes table saws do come with a fence included however most of the time this fence isnt durable enough meaning you might want to make your own or buy a more professional one. Attach the fence lock to the edge of the bolt on the slider. Holes were drilled and tapped every 6 inches 15241mm to hold studs I made out of 14x20 threaded rod I dont do metric hardware The 2 inch 508mm H Beam was drilled with clearance holes to accept the studs. It sits to the right of the table saw blade and is used to keep your board in place as you make a rip cut along the grain.

Diy Table Saw Fence Table Saw Diy Table Saw Fence Table Saw Accessories Table Saw Fence From pinterest.com

Diy Table Saw Fence Table Saw Diy Table Saw Fence Table Saw Accessories Table Saw Fence From pinterest.com

But if you still feel the need to remove the fence make sure that you keep it somewhere close to the table saw so that you wont have to search the entire house. The squareness is adjusted with the Horizontal Adjustment Plate. The table saw fence is one of the most underrated parts of a table saw without a good fence your cutting would be all over the place as there would be no guide for your work. Sometimes table saws do come with a fence included however most of the time this fence isnt durable enough meaning you might want to make your own or buy a more professional one. This way you can quickly start the table saw and get to work without having to get into the hassle of assembling the fence over and over again. You will also see how to set your fence at a perfect 90-degree angle with the.

You will also see how to set your fence at a perfect 90-degree angle with the.

Now after arranging the tools and material lets start making a table saw fence. Your fence should be about an inch. Plans for this project herehttpwwwibuilditcaSalessales-15htmlPlease check out the build article for more detailshttpwwwibuilditcaWorkshop20P. Holes were drilled and tapped every 6 inches 15241mm to hold studs I made out of 14x20 threaded rod I dont do metric hardware The 2 inch 508mm H Beam was drilled with clearance holes to accept the studs. Just off of the surface of the Table I and partly so that it doesnt fall when you move your fence way off to the right. Do you want to make a Cross Cut Sled for your table saw.

Source: pinterest.com

Source: pinterest.com

You will also see how to set your fence at a perfect 90-degree angle with the. It sits to the right of the table saw blade and is used to keep your board in place as you make a rip cut along the grain. The squareness is adjusted with the Horizontal Adjustment Plate. A table saw fence is meant to remain connected to the table saw. This way you can quickly start the table saw and get to work without having to get into the hassle of assembling the fence over and over again.

Source: pinterest.com

Source: pinterest.com

The end piece should be fitted with a twist nut which you can tighten by turning the nut against the table saw. Fabrication Of Aluminum Rail First Take the rectangular aluminum shape and try to have a 9mm groove in the middle by using the saw to make two passes. For screws countersink and drill at least five holes. Your fence should be about an inch. But if you still feel the need to remove the fence make sure that you keep it somewhere close to the table saw so that you wont have to search the entire house.

Source: pinterest.com

Source: pinterest.com

This is a piece of angle-iron welded to the Fence Tube F which keeps it square to the Guide Tube B. Turn on your saw and test run the fence with a piece of scrap wood. A table saw fence also called a rip fence is one of those essential table saw accessories that aid you in making accurate cuts. Dont forget to check the locking mechanism. Making sure you have everything you need before you start will ensure the building of your table saw fence goes off without a hitch.

Source: pinterest.com

Source: pinterest.com

But if you still feel the need to remove the fence make sure that you keep it somewhere close to the table saw so that you wont have to search the entire house. Making sure you have everything you need before you start will ensure the building of your table saw fence goes off without a hitch. Holes were drilled and tapped into the legs to match the existing holes on the table saw table. Tape measure 1 24 longer than your table saw depth Wood screws. This will help keep the wood from moving as you work.

Source: pinterest.com

Source: pinterest.com

Use four 25 millimeter screws to attach the fence to the slider top. This is how you do it. Do you want to make a Cross Cut Sled for your table saw. The end piece should be fitted with a twist nut which you can tighten by turning the nut against the table saw. This is a piece of angle-iron welded to the Fence Tube F which keeps it square to the Guide Tube B.

Source: pinterest.com

Source: pinterest.com

A table saw fence is meant to remain connected to the table saw. Do you want to make a Cross Cut Sled for your table saw. You will need the following materials to build your table saw fence. Dont forget to check the locking mechanism. The table saw fence is one of the most underrated parts of a table saw without a good fence your cutting would be all over the place as there would be no guide for your work.

Source: pinterest.com

Source: pinterest.com

Attach the fence lock to the edge of the bolt on the slider. Holes were drilled and tapped every 6 inches 15241mm to hold studs I made out of 14x20 threaded rod I dont do metric hardware The 2 inch 508mm H Beam was drilled with clearance holes to accept the studs. Pass the threaded rod through the hole and screw it into place. Just off of the surface of the Table I and partly so that it doesnt fall when you move your fence way off to the right. Use four 25 millimeter screws to attach the fence to the slider top.

Source: pinterest.com

Source: pinterest.com

The squareness is adjusted with the Horizontal Adjustment Plate. We wont be building this. Use a straight scale to confirm that the rip fence is parallel against the blade. Your fence should be about an inch. Pass the threaded rod through the hole and screw it into place.

Source: pinterest.com

Source: pinterest.com

Your fence should be about an inch. But if you still feel the need to remove the fence make sure that you keep it somewhere close to the table saw so that you wont have to search the entire house. Do you want to make a Cross Cut Sled for your table saw. This will help keep the wood from moving as you work. Making sure you have everything you need before you start will ensure the building of your table saw fence goes off without a hitch.

Source: pinterest.com

Source: pinterest.com

Just off of the surface of the Table I and partly so that it doesnt fall when you move your fence way off to the right. Use a straight scale to confirm that the rip fence is parallel against the blade. This is a piece of angle-iron welded to the Fence Tube F which keeps it square to the Guide Tube B. Turn on your saw and test run the fence with a piece of scrap wood. It sits to the right of the table saw blade and is used to keep your board in place as you make a rip cut along the grain.

Source: pinterest.com

Source: pinterest.com

We wont be building this. It sits to the right of the table saw blade and is used to keep your board in place as you make a rip cut along the grain. Holes were drilled and tapped every 6 inches 15241mm to hold studs I made out of 14x20 threaded rod I dont do metric hardware The 2 inch 508mm H Beam was drilled with clearance holes to accept the studs. For the sliding bolts this will be a proper slot. We wont be building this.

Source: pinterest.com

Source: pinterest.com

A table saw fence also called a rip fence is one of those essential table saw accessories that aid you in making accurate cuts. This is how you do it. Tape measure 1 24 longer than your table saw depth Wood screws. Making sure you have everything you need before you start will ensure the building of your table saw fence goes off without a hitch. Pass the threaded rod through the hole and screw it into place.

Source: sk.pinterest.com

Source: sk.pinterest.com

The squareness is adjusted with the Horizontal Adjustment Plate. Holes were drilled and tapped into the legs to match the existing holes on the table saw table. Tape measure 1 24 longer than your table saw depth Wood screws. This will help keep the wood from moving as you work. Just off of the surface of the Table I and partly so that it doesnt fall when you move your fence way off to the right.

Source: pinterest.com

Source: pinterest.com

Fabrication Of Aluminum Rail First Take the rectangular aluminum shape and try to have a 9mm groove in the middle by using the saw to make two passes. The squareness is adjusted with the Horizontal Adjustment Plate. Fabrication Of Aluminum Rail First Take the rectangular aluminum shape and try to have a 9mm groove in the middle by using the saw to make two passes. Use a straight scale to confirm that the rip fence is parallel against the blade. This is how you do it.

Source: tr.pinterest.com

Source: tr.pinterest.com

A table saw fence also called a rip fence is one of those essential table saw accessories that aid you in making accurate cuts. Another way to make a table saw fence is to use a 24 wood board some other wood pieces and a threaded rod clamp. Turn on your saw and test run the fence with a piece of scrap wood. This will help keep the wood from moving as you work. Do you want to make a Cross Cut Sled for your table saw.

Source: pinterest.com

Source: pinterest.com

For screws countersink and drill at least five holes. Use four 25 millimeter screws to attach the fence to the slider top. Pass the threaded rod through the hole and screw it into place. Plans for this project herehttpwwwibuilditcaSalessales-15htmlPlease check out the build article for more detailshttpwwwibuilditcaWorkshop20P. Holes were drilled and tapped into the legs to match the existing holes on the table saw table.

Source: pinterest.com

Source: pinterest.com

Holes were drilled and tapped into the legs to match the existing holes on the table saw table. Making sure you have everything you need before you start will ensure the building of your table saw fence goes off without a hitch. We wont be building this. Pass the threaded rod through the hole and screw it into place. You will only need a few simple supplies to make your table saw fence.

Source: pinterest.com

Source: pinterest.com

Use four 25 millimeter screws to attach the fence to the slider top. Fabrication Of Aluminum Rail First Take the rectangular aluminum shape and try to have a 9mm groove in the middle by using the saw to make two passes. Turn on your saw and test run the fence with a piece of scrap wood. Pass the threaded rod through the hole and screw it into place. This will help keep the wood from moving as you work.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to make a table saw fence by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.